Refrigeration Basics

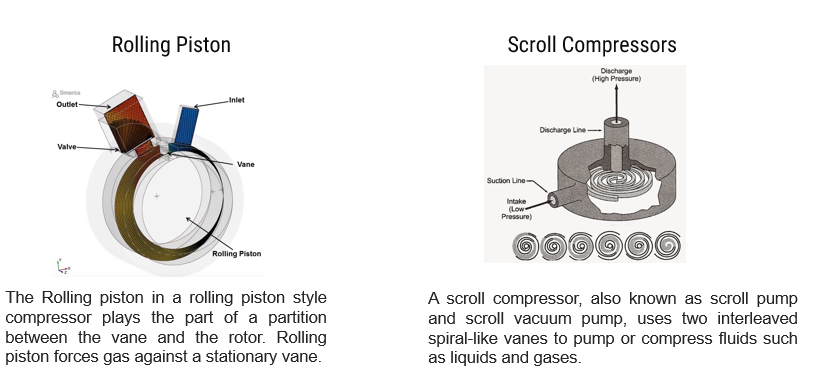

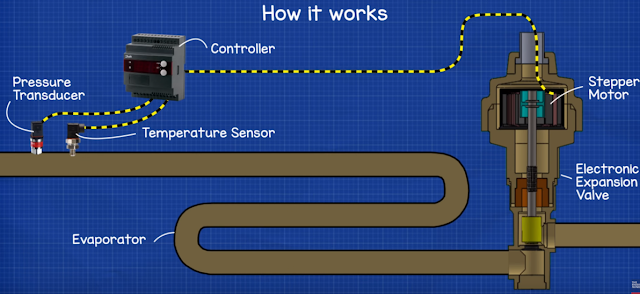

Mechanical refrigeration system contain 4 main components. Any components beyond these basic 4 are called accessories. The compressor is a vapour compression pump which uses pistons or some other method to compress the refrigerant gas and send it on it's way to the condenser. The condenser is a heat exchanger which removes heat from the hot compressed gas and allows it to condense into a liquid. The liquid refrigerant is then routed to the metering device. This device restricts the flow by forcing the refrigerant to go through a small hole which causes a pressure drop. It lowers the boiling point and makes it easier to evaporate.

This component where the evaporation takes place is called the evaporator. The refrigerant is then routed back to the compressor to complete the cycle. The refrigerant is used over and over again absorbing heat from one area and relocating it to another. Heat Transfer Rates One thing that we would like to optimize in the refrigeration loop is the rate of heat transfer. Refrigeration heat transfer devices such as air cooled condensers and evaporators are often made out of copper pipes with aluminum fins and further enhanced with fans to force air through the fins.

There should be a full column of high pressure liquid refrigerant (in the liquid line) supplying the inlet of the metering device. When it is forced to go through a small orifice it loses a lot of the pressure it had on the upstream side of the device. The liquid refrigerant is sort of misted into the evaporator. So not only is the pressure reduced, the surface area of the liquid is vastly increased.

The Condenser

vThe hot vapor enters the condenser and starts to flow through the tubes.

vCool air is blown across the outside of the finned tubes of the condenser usually by a fan.

vSince the air is cooler than the refrigerant, heat is transfered from the tubing to the cooler air.

vAs the heat is removed from the refrigerant, it reaches its saturated temperature and starts to change state into a high pressure liquid. In other words, the refrigerant condenses. At the end of condensing, the refrigerant becomes high pressure saturated liquid. However, due to further heat rejection, the refrigerant leaves the condenser as high pressure subcooled liquid.

vThe high pressure liquid leaving the condenser enters the liquid line and goes to the expansion device. A filter drier is usually placed between the condenser and expansion device to remove any dirt or foreign particles.

The Evaporator

vThe evaporator is located to the place where the heat is removed from the air stream to be cooled.

vLow pressure and low temperature mixture of saturated liquid and saturated vapour leaves the expansion device, and enters the evaporator.

vUsually, a fan will move warm air across the evaporator finned coils.

vBecause the refrigerant in the evaporator tubes is cooler than the air stream, the refrigerant absorbs heat from the warm air stream, and evaporates. Towards the outlet of the evaporator, the refrigerant becomes low pressure saturated vapour. As a result of further heat absorbtion, the refrigerant leaves the evaporator as low pressure and low temperature superheated vapour.

vThen, this low pressure vapour is pulled into the compressor through the suction line, and the cycle starts over.

Engine Cooling

Radiators are used for cooling internal combustion engines. To cool down the engine, a coolant is passed through the engine block, where it absorbs heat from the engine. The hot coolant is then fed into the inlet tank of the radiator (located either on the top of the radiator, or along one side), from which it is distributed across the radiator core through tubes to another tank on the opposite end of the radiator. As the coolant passes through the radiator tubes on its way to the opposite tank, it transfers much of its heat to the tubes which, in turn, transfer the heat to the fins that are lodged between each row of tubes. The fins then release the heat to the ambient air. Fins are used to greatly increase the contact surface of the tubes to the air, thus increasing the exchange efficiency. The cooled coolant is fed back to the engine, and the cycle repeats. Normally, the radiator does not reduce the temperature of the coolant back to ambient air temperature, but it is still sufficiently cooled to keep the engine from overheating.